Non-Destructive Testing

Non-Destructive Testing (NDT) is a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage. Anything can be closely inspected without removing so much a screw. Our NDT services mainly includes:

Magnetic Particle Testing

The basics of MT is to create a magnetic field within a ferrous material and then dust its surface with iron particles, and watch for where they accumulate. It shows the structural weaknesses of the material. MT easily detects surface cracks and other discontinuities in a cost-effective manner.

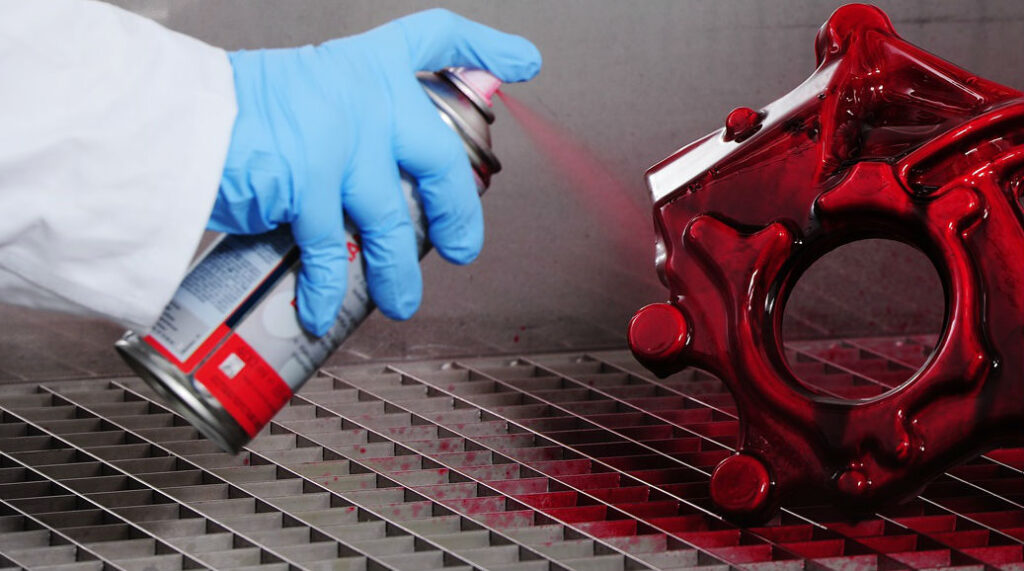

Dye Penetrant Testing

The process is to apply strong dye on pipes, and then allow it to penetrate inside it. The excess penetrant is then removed and a developer is applied which makes the cracks and anomalies visible. This is a cost-effective test that generally works best on casting, forging, and welding surface defects.

Ultrasonic Testing

Ultrasonic tests employ high frequencies to measure pipes and tanks externally and internally. UT can be conducted on both ferrous and non-ferrous materials, and it may detect cracks missed by other tests. UT detects even the smallest flaws that are non-hazardous to conduct and is portable.

Positive Material Identification

A rapid, non-destructive method, positive material identification is performed on a wide range of components and assets and provides semi-quantitative chemical analysis. It is used for both material verification and identification. Positive material identification can prevent potential product failure in manufacturing. At oil and gas, power generation and pharmaceutical plants, pre-service and in-service inspection of critical components and welds with PMI can prevent breakdown and its costly consequences.